Recently, Jiahe Maintenance and Remanufacturing Service Center was entrusted by the customer to provide professional maintenance services for BB1 and BB3 imported main oil transfer pumps for the maintenance. During the overhaul inspection, serious erosion and wear problems occurred in the pump casing flow channel, sealing cavity and rotor components of this batch of main oil transfer pumps. Jiahe's service team acted quickly and organized an efficient team to carry out detailed survey work. At the same time, it also held a technical research meeting to discuss and formulate the optimal maintenance plan with customers.

The service team through the professional inspection of damaged parts, and then through the latest remanufacturing technology to repair the components need to repair, according to customer requirements to further upgrade the pump wear-resistant components, so as to fully improve the performance of the pump. In order to ensure the repair quality of the components and the consistency and adaptability of the new components with the original pump operation, the service team carried out rotor dynamic balance test, hydrostatic pressure test, performance and mechanical operation test, and finally the repaired product performance restored all functions, reached the standard of the new product, and effectively extended the service life of the pump. Jiahe Maintenance and Remanufacturing Service Center injects new vitality into the pump with efficient and professional services, realizes the service demand of shortening maintenance cycle and improving cost-effectiveness for users, and provides strong guarantee for key pumps used in industrial project installations!

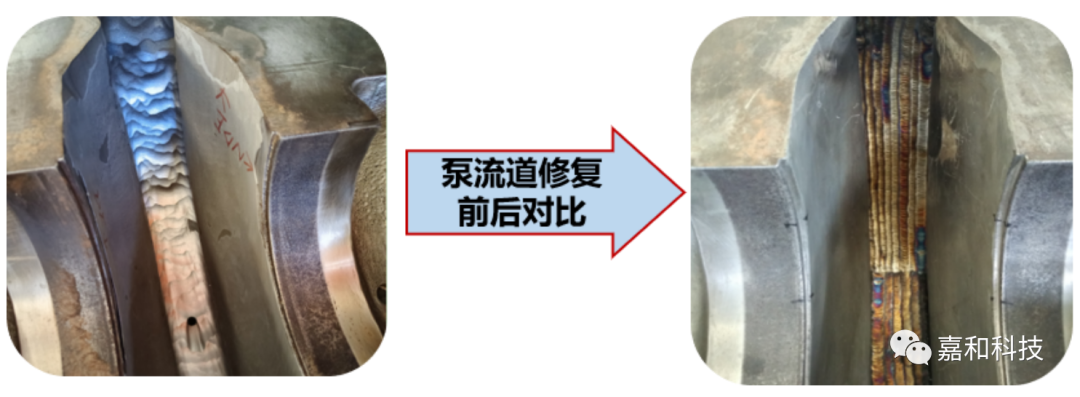

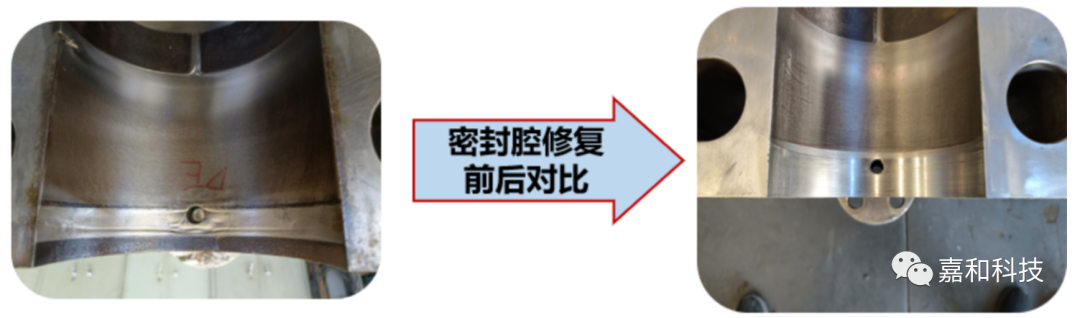

Maintenance effect( comparison of the pump casing flow channel before and after repair、comparison of sealing cavity before and after repair)

Jiahe Maintenance and Remanufacturing Service Center has trained a group of professional craftsmen around the goal of "domestic optimization and import substitution" of key pumps in the industry field, combined with the practice and experience of users and industry experts in key pumps in core devices, as well as the core advantages of successfully replacing imports with many products independently developed, and has been committed to providing imported pump maintenance and remanufacturing services for industry users for many years, provide short-cycle economic maintenance services for industry users, while ensuring the quality of maintenance, can greatly shorten the equipment maintenance time, save maintenance costs, can reduce the operation and maintenance costs of imported high-end pumps for enterprises by more than 30%, and ensure the efficient operation of the key pumps of the device "safe, stable, long, full and excellent!